Tradition

Tradition

Already since 75 years and by that in the third generation,

leather bags and small leather items are handcrafted in

our manufactory.

Starting with the choice of materials, we pay attention to the origin and the quality of the leather that we use for our leather goods. For example our black-colored leather comes from cows that grew up at the Allgaeu in Germany, which allows, due to the short distances, the processing of the leather without the use of preservatives and additives in the tannery.

Colored leather we receive from Germany or Italy, also from long-term suppliers, who pay particular attention to the quality and origin of their leather hides.

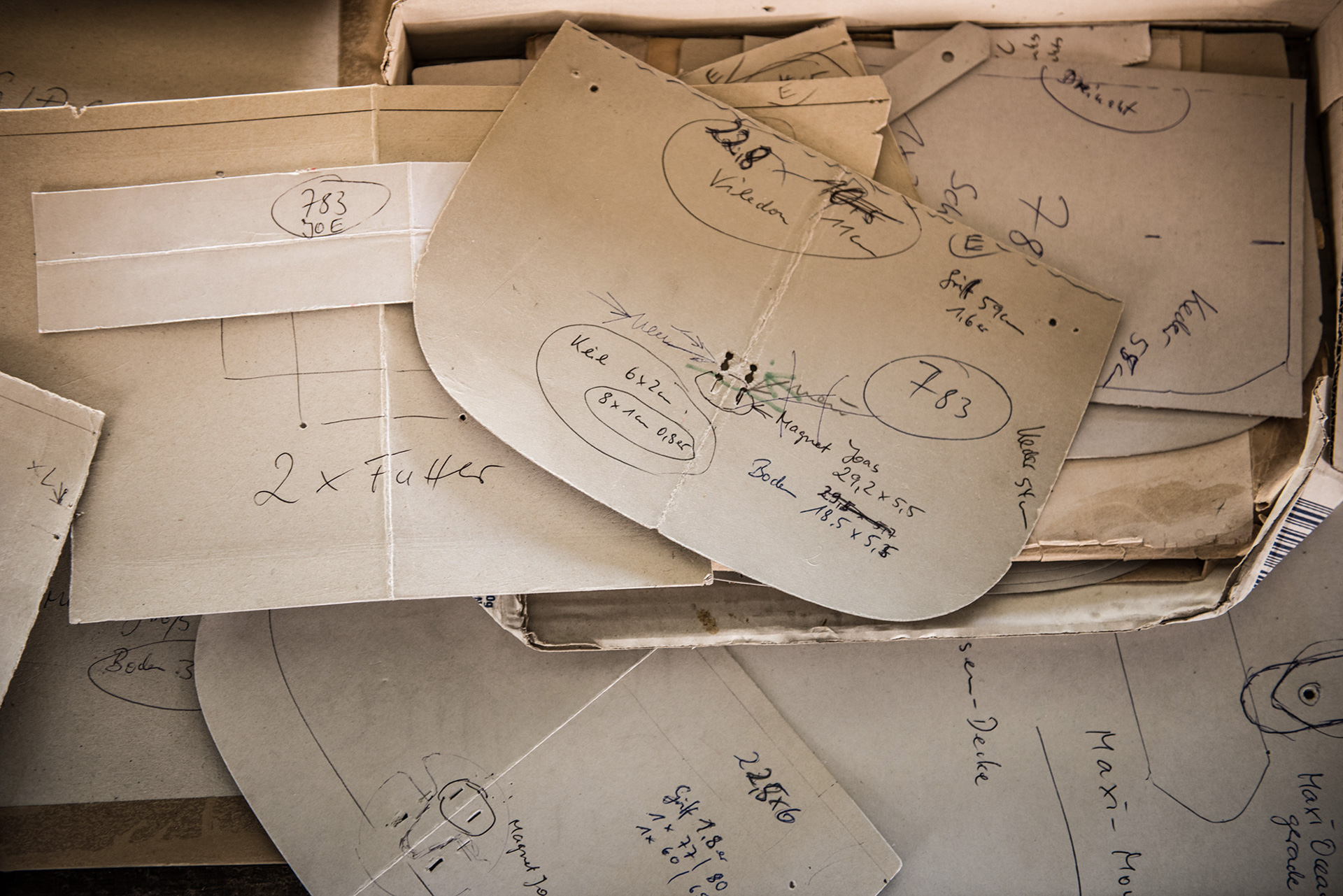

In our factory, these leather hides are trimmed and processed by our expertly trained staff. Sometimes even by the grandfather

who is still working from time to time in the manufactory and

has lost none of his skills. In addition, our young employees

can learn from his priceless and unique manufacturing knowledge.

Innovation

Innovation

The skills to process leather into exclusive bags is a key success factor for D vs. B. Another success factor is to attract new and existing customers with new and special products.

D vs. B attaches great importance to the development of its own product range continuously.

For this purpose, for example, the range of different bag models and small leather parts steadily increases. Either by the revival of old designs from the 50’s or by a totally new development of new designs.

In the area of the material usage, D vs. B is continuously looking for new materials and develops new manufacturing solutions to handle fabrics and materials from other industrial segments.

So happened at the legendary BurnOut fabric that was ready for series production after two years of development and countless tests.

However, the processing of the original seat cover fabrics from classic cars is also an innovation for D vs. B. Just as the usage of real carbon leather, embroideries, and embossments or – band new – the printing of leather without chemical additives.

Story Behind

Story Behind

Ben Johl and Thomas Gruenewald are the founders of Destroy vs. Beauty and closely linked to the region of Frankfurt / Main.

Family Johl reached worldwide recognition in the leather industry with the luxury brand “SEEGER” that stood over decades for innovative leather products and unique manufacturing quality.

Already for the Porsche 356 they developed a special suitcase that fitted perfectly into the car’s luggage compartment.

Ben learned the trade from scratch with his father. And he has deepened and broadened his knowledge by means of studies in the USA. But more importantly, he has inherited his father's talent - and is putting it to good use. He has courageously stepped out of his father's shadow with a sensationally creative product idea.

Whereas his father used to design noble, custom-made individual pieces with consummate craftsmanship, Ben is now turning the tables - without, of course, shaking the idea of the "one-off". He destroys materials and thus creates a new, unique aesthetic. In short, his products live from a whole new, unprecedented authenticity.

“With the manufactory site in the region of Frankfurt, we not only secure jobs, but also our unique production knowledge from 75 years of leather processing. The cooperation with regional partners and suppliers also means that we are incredible flexible. Unlike other luxury brands that today produce in the Far East bags and thus have to plan on large batch sizes, we are able to realize unique items or small batches on demand.” Says Benjamin Johl.

In order to realize the brand‘s philosophy “Handcrafted in Germany” and to stand out from other luxury brands, D vs. B stroke out on new paths and changed its previous product strategy fundamentally.

Together with Thomas Gruenewald, an experienced buyer and also creative head, the two founders finally succeeded after 2 years of development with the first BurnOut Bag. A breakthrough caused by the transformation of a traditional leather good in an automotive-related lifestyle product for a new audience.

Thomas Gruenewald: “Of course, that sounded at the beginning kind of “cuckoo”. To run over a fine fabric with a luxury sports car and afterwards to turn that fabric into a luxury handbag. But in the end that idea in conjunction with a classic bag design and the unique manufacturing quality fitted exactly the taste of our customers.”

Today D vs. B is more than an insider tip for automotive enthusiasts. With additional collections produced without tire printings, the brand attracts customers all over the world that search for exceptional products – made in Germany.

Ben Johl: “With the BurnOut Bag Collection we draw attention at a large group of national and international customers. With our current product range, we focus ourselves on our core competence of individual leather processing to create unique luxury products for customers who demand a personalization of bags that cannot be fulfilled by established luxury brands.”